-

Contact

|

-

Wechat

Wechat:tel-15397675238Scan Contact

|

CHINESE |

CHINESE |

Русский язык

Русский язык

Wechat:tel-15397675238Scan Contact

CHINESE

CHINESE Русский язык

Русский язык

![[list:title]](https://www.hc986.com/static/upload/image/20250127/1737955364387567.jpg)

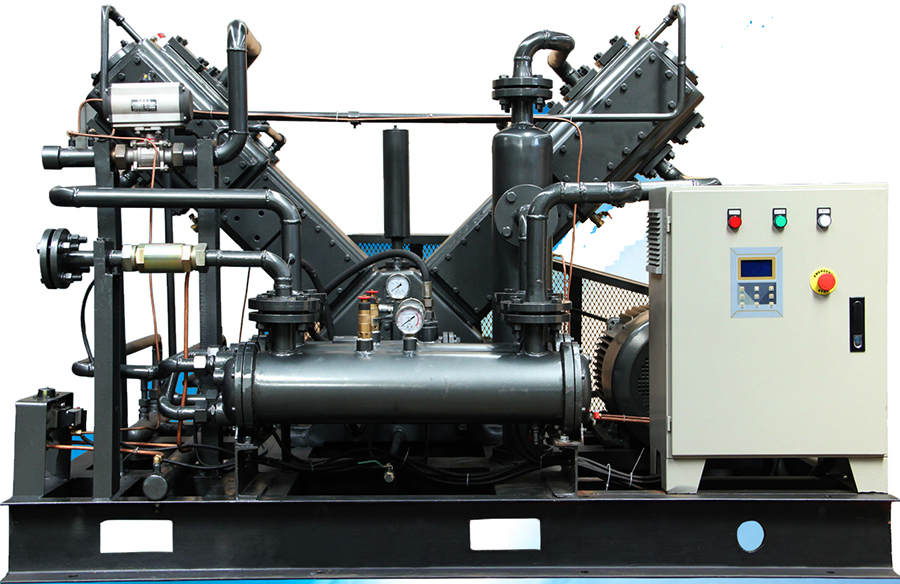

Product parameters:

Model: LHC-8/40 Water-cooled Oil-free Booster Compressor for PET Bottle Blowing

Power: 37KW

Displacement (m³/min): 8 m³ /min

Intake pressure: 10 bar

Exhaust pr···

Product parameters:

Model: LHC-8/40 Water-cooled Oil-free Booster Compressor for PET Bottle Blowing

Power: 37KW

Displacement (m³/min): 8 m³ /min

Intake pressure: 10 bar

Exhaust pressure: 40 bar

Lubrication method: Oil-free lubrication of cylinder block

Compression method: Piston

Intake port: G1 1/2"

Exhaust port: DN35

Water inlet: G1 1/2"

Drainage interface: G1 1/2"

Weight: 1560

External dimensions: 230*150*145cm

Product Description:

Haocheng Company's water-cooled oil-free booster compressors are characterized by stable operation, low failure rate, convenient maintenance, low maintenance costs, oil-free lubrication of gas contact parts, and clean compressed gas, receiving unanimous praise from users. This unit uses water cooling to ensure long-term continuous operation at low temperatures, and uses PLC program control to monitor equipment operation, enabling unattended operation and fault reporting shutdown. All supporting components are from well-known domestic brands, and the core components of the main unit are manufactured using standard processes, ensuring the machine's durability and greatly extending its service life. It is mainly used for PET bottle blowing, filling machine gas supply, nitrogen boosting, and other applications with large gas consumption.

Main supply scope:

booster compressor main unit

drive motor

Transmission system

Circulatory system

control system

Safety devices

alarm device

Cooling device

Base

Documents (including operation manuals and parts manuals)

Composition and operating principle of the booster unit:

1. Crankcase components

The crankcase is equipped with an oil level sight glass, a breather, and a gear oil pump; the bottom of the crankcase contains an oil filter.

2. Crankshaft, connecting rod, and components

The crankshaft has connecting rods mounted on its bearings, rolling bearings at both ends, and a pulley at its large end for rotation. Lubrication is provided by a geared oil pump supplying oil to the crankshaft and crosshead pins.

3. Guide cylinder assembly

The guide cylinder contains a crosshead and crosshead pin, along with an oil ring, to separate the oil from the cylinder.

4. Cylinder components

The cylinder has inlet and outlet ports to increase water circulation within it. Inlet and outlet valves are installed on both sides of the cylinder. Inside the cylinder are a piston and piston rod, connected to a crosshead screw. A packing seal is installed at the bottom of the cylinder.

5. Piston assembly

Two sets of piston components, each with an aluminum alloy piston and equipped with oil-free piston rings and support rings.

6. Intake and exhaust valves

Inlet and exhaust valves are steel components and combination valves

7. Piping section

Both the inlet and outlet ports are made of welded stainless steel pipes, and there are safety valves on both pipes.

Force sensors and temperature sensors

8. Cooler components

The cooler consists of three groups: an oil cooler, a primary air cooler, and a secondary air cooler. Cooling is achieved by a water pump entering the cooler interface, and a water pressure sensor is installed at the pump outlet.

Control system:

1. The main unit is equipped with a control cabinet.

2. The control cabinet panel has a controller.

3. The compressor inlet is equipped with an automatic feed valve.

4. The booster compressor's secondary intake is equipped with an oil-water separator with automatic water drainage.

5. The booster compressor is equipped with a vent valve. Upon reaching the rated pressure, it automatically vents, allowing the booster compressor to operate under no-load conditions.

6. Both units are equipped with temperature sensors; if the temperature is too high, an alarm will sound and the unit will automatically shut down.

7. Both units are equipped with pressure sensors. If the pressure in either unit exceeds the set pressure, an alarm will sound and the unit will automatically shut down.

8. Water pressure sensor: If the pressure drops below the set level, the machine will automatically alarm and shut down.

9. The oil pressure sensor automatically alarms and shuts down when the pressure drops below the set level.

The advantages of oil-free, water-cooled booster air compressors are mainly as follows:

High air quality: Oil-free water-cooled air compressors do not use lubricating oil during the compression process, so the compressed air produced contains almost no oil molecules, which can ensure the purity of the compressed air and avoid oil contamination of products.

Simple maintenance: The absence of a traditional oil lubrication system reduces the need for lubricant use and replacement, lowers maintenance costs, and simplifies the maintenance process. Users only need to perform basic maintenance periodically, such as cleaning the filter, to ensure the air compressor operates smoothly.

Significant energy savings: Water has excellent thermal conductivity, allowing water-lubricated air compressors to transfer heat from friction surfaces, reducing heat buildup and improving compression efficiency. Furthermore, the absence of lubricating oil reduces operating costs, and oil-free air compressors can operate across a wide range of discharge volumes, automatically adjusting motor speed in real-time based on actual air consumption, thus reducing energy waste and power consumption.

High safety: Because oil-free air compressors do not use lubricating oil, they avoid fires or other safety accidents caused by lubrication problems. At the same time, oil-free air compressors have a smaller impact on the power grid during startup, helping to protect the integrity of the entire mechanical system.

High temperature adaptability: Water has good thermal stability, and water-lubricated air compressors can operate in high-temperature environments.

High reliability: It avoids problems such as lubricant contamination and friction surface damage, thus having high reliability and reducing failure rate and downtime.

Long lifespan: It has no problems such as friction surface damage and lubricant contamination, so it has a long lifespan and can operate stably for a long time.

In summary, Haocheng's oil-free water-cooled booster air compressor demonstrates significant advantages in multiple aspects, making it an ideal choice for numerous industries. With continuous technological advancements and increasing application demands, oil-free water-cooled air compressors are expected to play an even more important role in the future, providing more efficient, environmentally friendly, and reliable compressed air solutions for industrial production.