-

Contact

|

-

Wechat

Wechat:tel-15397675238Scan Contact

|

CHINESE |

CHINESE |

Русский язык

Русский язык

Wechat:tel-15397675238Scan Contact

CHINESE

CHINESE Русский язык

Русский язык

![[list:title]](https://hc986.com/static/upload/image/20250126/1737883438102713.jpg)

Product parameters:

Model: HC-1.5/350 Industrial Grade High Pressure Air Compressor

Exhaust volume: 1.5 m³/min

Pressure: 35 MPa

Compression levels: Five-level···

Product parameters:

Model: HC-1.5/350 Industrial Grade High Pressure Air Compressor

Exhaust volume: 1.5 m³/min

Pressure: 35 MPa

Compression levels: Five-level compression

Power: 37 KW

Rotational speed: 980 r/min

Weight: 1600KG

Electrical system: 380V 50HZ

External dimensions: 2300×1650 ×1400 mm

Lubrication method: Splash lubrication

Product features: PLC control, automatic start/stop, automatic sewage discharge, overload protection, phase sequence protection, phase loss protection, low oil protection, pressure monitoring, and temperature monitoring.

Working principle of Haocheng high-pressure air compressor products

This product is mass-produced based on a modified and optimized German design. The final stage piston uses titanium nitride technology, the piston rings use Riken technology from Japan, and all castings are outsourced to large, specialized factories. Having been on the market for over ten years, it has received consistent praise from users. Furthermore, our production process surpasses that of other domestic companies. This product employs a five-cylinder, five-stage compression system, splash lubrication, interstage safety valves, and a filtration system. The HC-1.5/350 can provide safe compressed air for any industry requiring a high-pressure air source. This product is designed, manufactured, and commissioned according to the requirements of GB/T 12929-2008 "Marine High-Pressure Piston Air Compressors." This product is an air compression device that compresses 1 kg of free air (1 bar/0.1 MPa) to a gauge pressure of 350 kg (350 bar/35 MPa) through a series of compressions. This air then passes through a separator and filter within the unit, removing oil and impurities contained in the high-pressure air, providing highly purified, clean, safe, and reliable compressed air.

Haocheng High Pressure Air Compressor Safety Protection

A: Protection of the motor

The air compressor controller has overload protection for the main motor. When a fault such as motor stall or overload occurs during machine operation, the motor stops running, and an alarm sounds to shut down the machine.

B: Intake overheat protection

When the intake air filter is clogged, the cooler is clogged, or the intake and exhaust valves are damaged, causing the intake air temperature to exceed the set high temperature limit, the controller will alarm and shut down.

C: Gas supply pressure overpressure protection

When the gas supply pressure exceeds the set pressure limit, the controller will alarm and shut down.

D: Oil shortage protection

When the crankcase is low on oil, the controller will alarm and shut down the machine to prevent it from operating without oil.

E: Timer function

This machine has a timed shutdown function for scheduled machine maintenance, and the password can be freely set.

Haocheng high-pressure air compressors are widely used in air tightness testing and air tightness experiments.

Ensuring equipment safety: Many industrial devices, such as gas cylinders, valves, pipelines, and pressure gauges, are subjected to high-pressure gas during operation. Air tightness testing using a high-pressure air compressor ensures that these devices will not leak gas under normal operating pressure, thus preventing safety accidents caused by leaks and ensuring stable equipment operation and operator safety.

Quality Control and Reliability Assessment: In the production process, for products with high sealing requirements, such as automotive parts and aerospace components, airtightness is one of the important quality indicators. Using a high-pressure air compressor to conduct airtightness tests can detect the presence of even minor leaks, helping to identify problems promptly and make improvements, thereby enhancing product quality and reliability.

Compliance with regulations and standards: In certain industries, such as special equipment manufacturing and chemical production, relevant regulations and standards clearly stipulate that equipment or containers must undergo rigorous airtightness testing and trials. High-pressure air compressors, as devices providing high-pressure gas sources, can meet these regulations and standards, ensuring that the products manufactured or the equipment used by the company comply with safety standards.

Reducing production costs and risks: If sufficient airtightness testing and trials are not conducted before equipment is put into use, gas leaks could lead to serious consequences such as production interruptions, product damage, and even personal injury, causing huge economic losses and reputational damage to the company. Using high-pressure air compressors for preventative airtightness testing can identify and resolve problems in advance, reducing potential risks and costs.

Providing high-pressure gas : Providing the necessary high-pressure gas for the airtightness testing of various high-pressure containers or pressure vessels such as gas cylinders, steel cylinders, valves, pipelines, pressure gauges, and high-pressure boilers to meet the testing pressure requirements.

Ensuring detection accuracy : It can output stable and continuous high-pressure gas, ensuring constant gas pressure during airtightness testing, thus making the test results more accurate and reliable. By precisely controlling the output pressure and flow rate, even minute leaks can be detected, improving detection sensitivity.

Ensuring equipment safety : In industries with extremely high safety requirements, such as aerospace, petrochemicals, and automobile manufacturing, high-pressure air compressors provide high-pressure gas for airtightness testing. This helps to identify potential safety hazards, ensure the safety of equipment and systems during operation, and prevent accidents caused by leaks and other problems.

Case study of meeting customer's batch testing needs for pressure gauges

I. Overview of Customer Needs

The customer requests batch testing of 100 pressure gauges, with the following specific requirements:

Test pressure: 150 bar

Pressure holding time: 30 minutes each time

II. Haocheng Company Solution

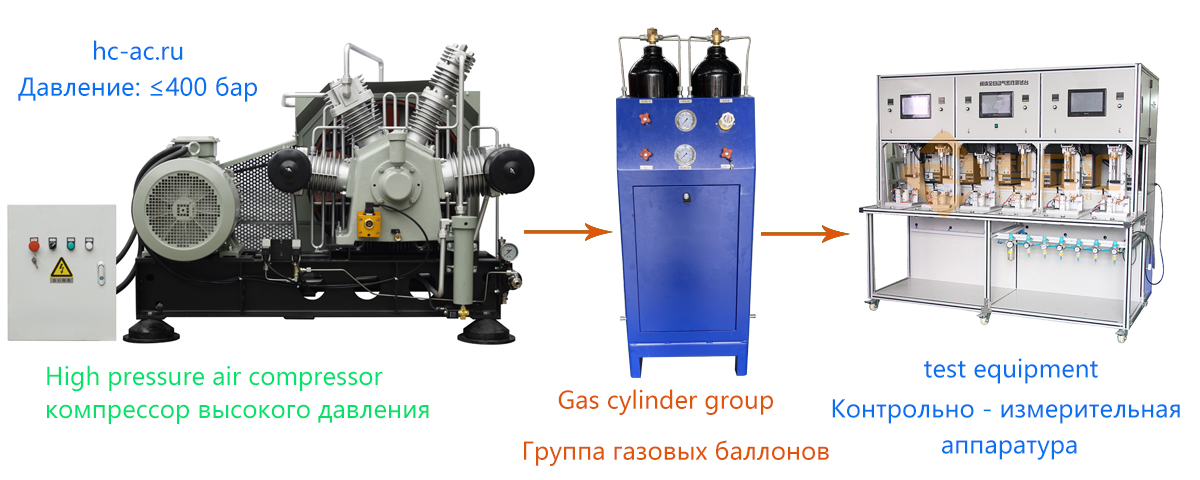

To meet customer needs, Haocheng Company, after detailed analysis and planning, has developed the following targeted solutions:

(a) Equipment selection

Based on the customer's specified testing pressure of 150 bar, Haocheng Company provided a stable and reliable 300 bar high-pressure air compressor. This air compressor possesses efficient and stable gas compression capabilities, fully meeting the customer's needs for a high-pressure gas source in pressure gauge leak testing, ensuring the smooth progress of the testing process.

(II) Configuration of High-Pressure Gas Cylinder Group

Considering the continuity and stability of the testing work, we selected a meticulously designed high-pressure gas cylinder assembly for our client. The specific configuration and features are as follows:

1. Gas cylinder assembly structure

The gas cylinder group consists of multiple gas cylinders that meet safety standards connected in series to form a unified gas supply system. This series structure design can effectively improve the gas storage capacity of the cylinder group and ensure a sufficient supply of high-pressure gas during long-term continuous testing.

2. Safety devices are equipped

To ensure the safety of the entire gas cylinder group during operation, we have installed a variety of safety devices on the gas cylinder group, including:

Pressure gauge: Real-time monitoring of gas pressure within the gas cylinder group, allowing operators to understand the pressure status of the gas cylinder group at any time, so as to make timely adjustments and decisions.

Safety valve: When the pressure inside the gas cylinder group exceeds the set safety value, the safety valve will automatically open to release excess gas and prevent safety accidents caused by excessive pressure.

Gate valve: Used to control the direction of gas flow, ensuring that gas can only flow along a predetermined path and preventing abnormal situations such as gas leakage or backflow.

Drain valve: Facilitates the periodic discharge of impurities and moisture from the gas cylinder assembly, maintaining gas purity and extending the service life of the gas cylinder assembly.

3. Pipeline connection

High-quality stainless steel piping is used to connect the gas cylinder assembly to the high-pressure air compressor and the customer's testing station. Stainless steel piping offers excellent corrosion resistance and sealing properties, enabling stable gas transmission under high pressure and effectively reducing the risk of gas leakage.

(III) Pressure Regulation and Control Function

To meet the precise gas pressure requirements of different testing scenarios, the gas cylinder group is equipped with an advanced pressure regulation and control system. This system has the following functions:

1. Adjustable pressure

Operators can freely set the output gas pressure value on the control interface according to actual testing needs. Whether it is a testing pressure of 150 bar or other specific pressure values, this system can accurately achieve them, meeting diverse testing requirements.

2. Intelligent start-stop control

When the gas cylinder pressure reaches the set upper limit, such as 300 bar, the high-pressure air compressor will automatically stop and cease filling the cylinder group. This is to prevent excessive pressure within the cylinder group and protect the safety of the cylinder group and related equipment. Conversely, when the pressure in the cylinder group falls below the set lower limit, such as 180 bar, the high-pressure air compressor will automatically restart and continue filling the cylinder group, ensuring a stable high-pressure gas output to the testing workbench and guaranteeing the continuity and stability of the testing operation.

III. Summary

By providing a 300-bar high-pressure air compressor and a carefully configured high-pressure gas cylinder assembly, Haocheng can fully meet customers' needs for batch testing of 100 pressure gauges. Our solution not only meets the requirements for testing pressure and holding time, but also ensures a stable gas pressure supply and safe and reliable equipment operation during the testing process through an intelligent pressure regulation and control system. Haocheng will continue to provide customers with high-quality products and services, helping them to conduct production testing work efficiently and smoothly.